Under the "dual carbon" goals, the rapid development of China's new energy vehicle industry and the rapid expansion of the power battery industry have directly driven growth in high demand for lithium battery testing equipment. According to statistics from the Passenger Federation, China sold almost 3 million energy vehicles in 2021, a year-on-year increase of 169.1%. The lithium battery manufacturing process is divided into the front process (pole piece manufacturing), the middle process (cell synthesis), and the back process (chemical packaging). Due to the high safety performance requirements of lithium-ion batteries, there are extremely high requirements for the precision, stability and automation level of lithium-ion batteries in the battery manufacturing process.

The internal structure of the manufactured lithium battery cannot be detected by general methods. X-ray testing equipment provides a reliable guarantee for the improvement of product quality. X-rays are sent out through the X-ray generator, penetrate the interior of the battery, receive X-ray imaging and photograph by the imaging system, process the images correctly and accurately measure and judge through professional software, detect the open circuit of the lithium electrode lug welding, detect whether there are displacement between anode and cathode alignment (rate), measure the distance between the positive and negative electrodes, welding of the missing installation of protective plate with the positive and negative electrodes, the internal defects of the lithium battery after packaging can be found intuitively through the inspection images, and control product quality.

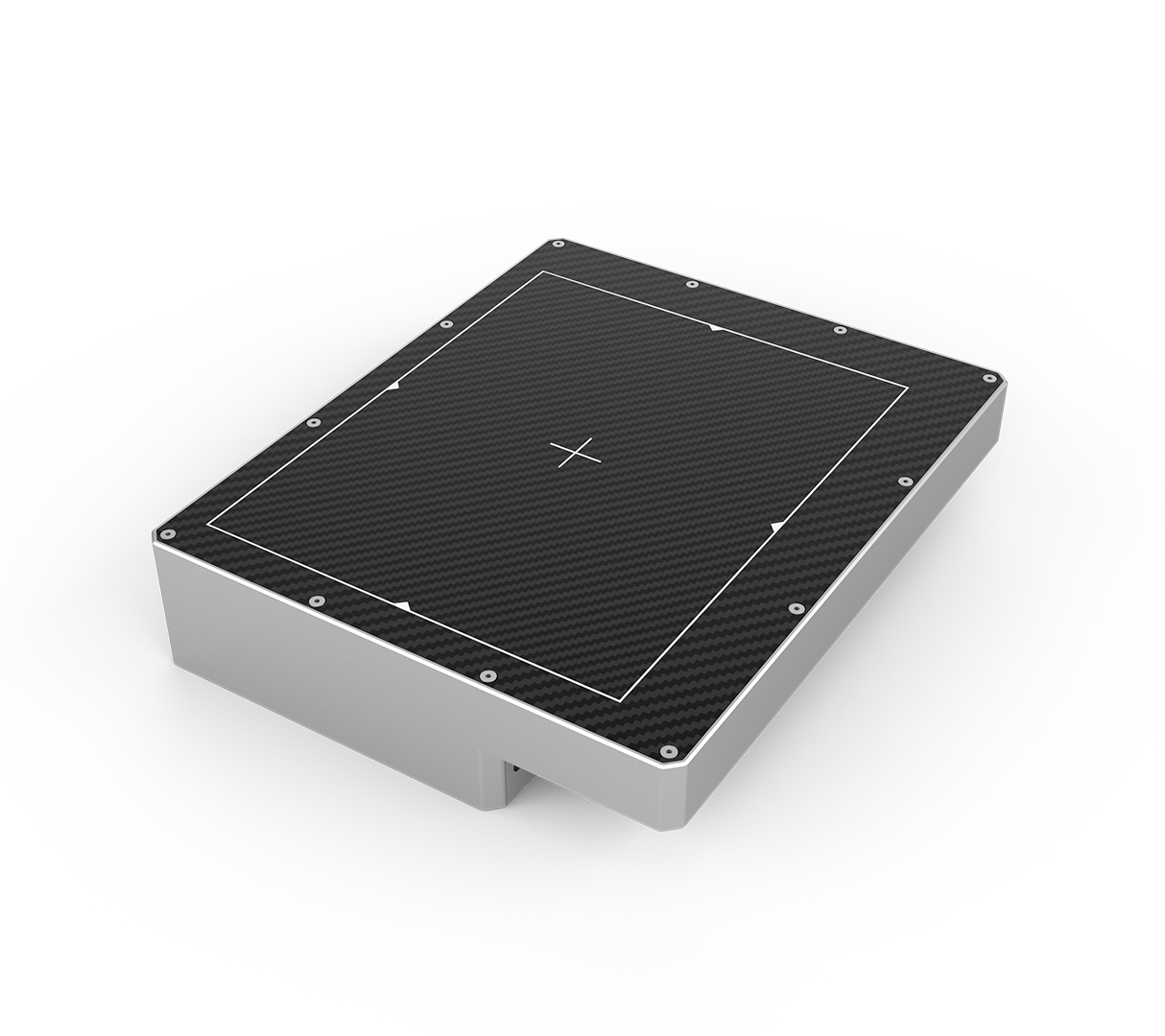

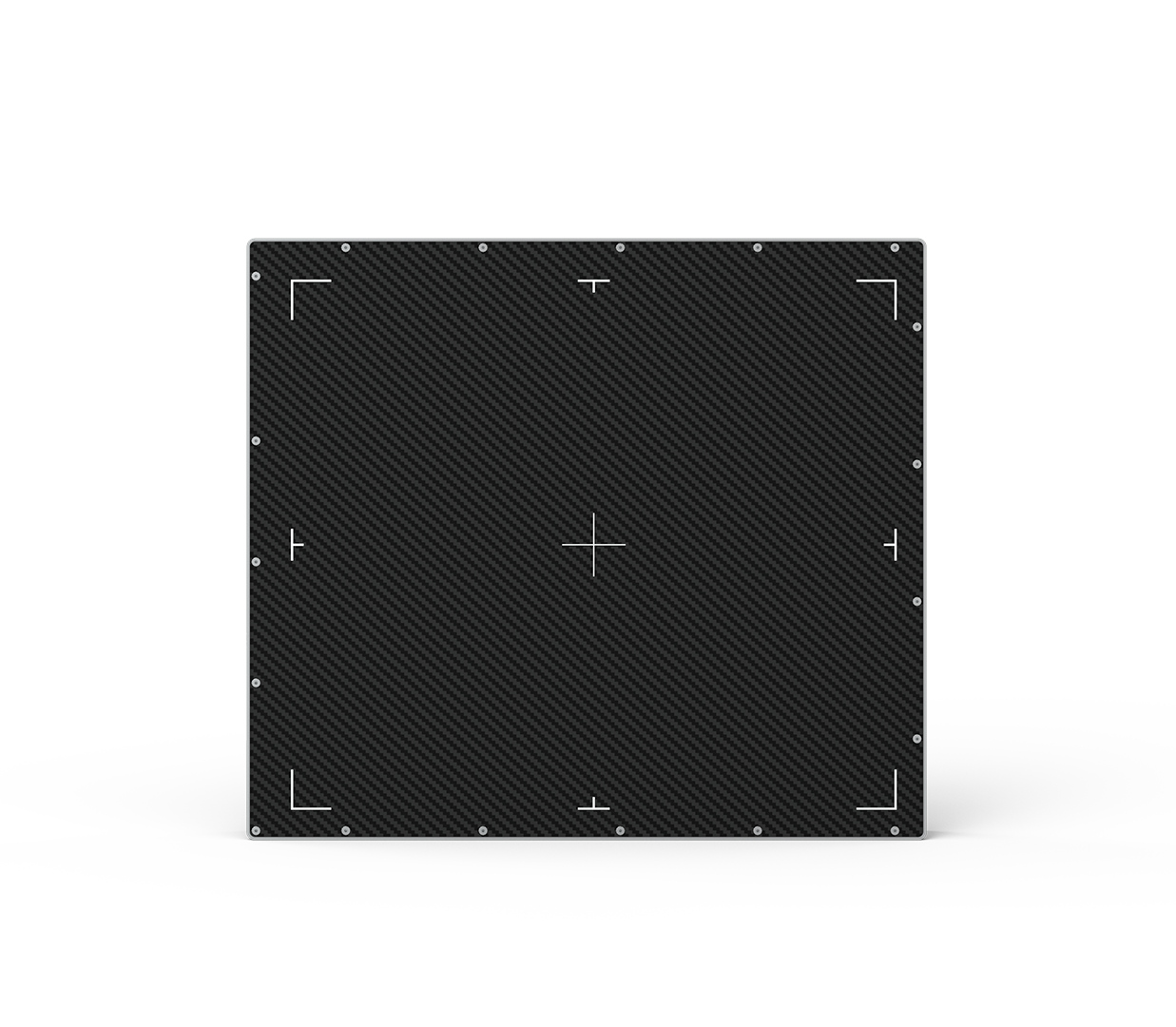

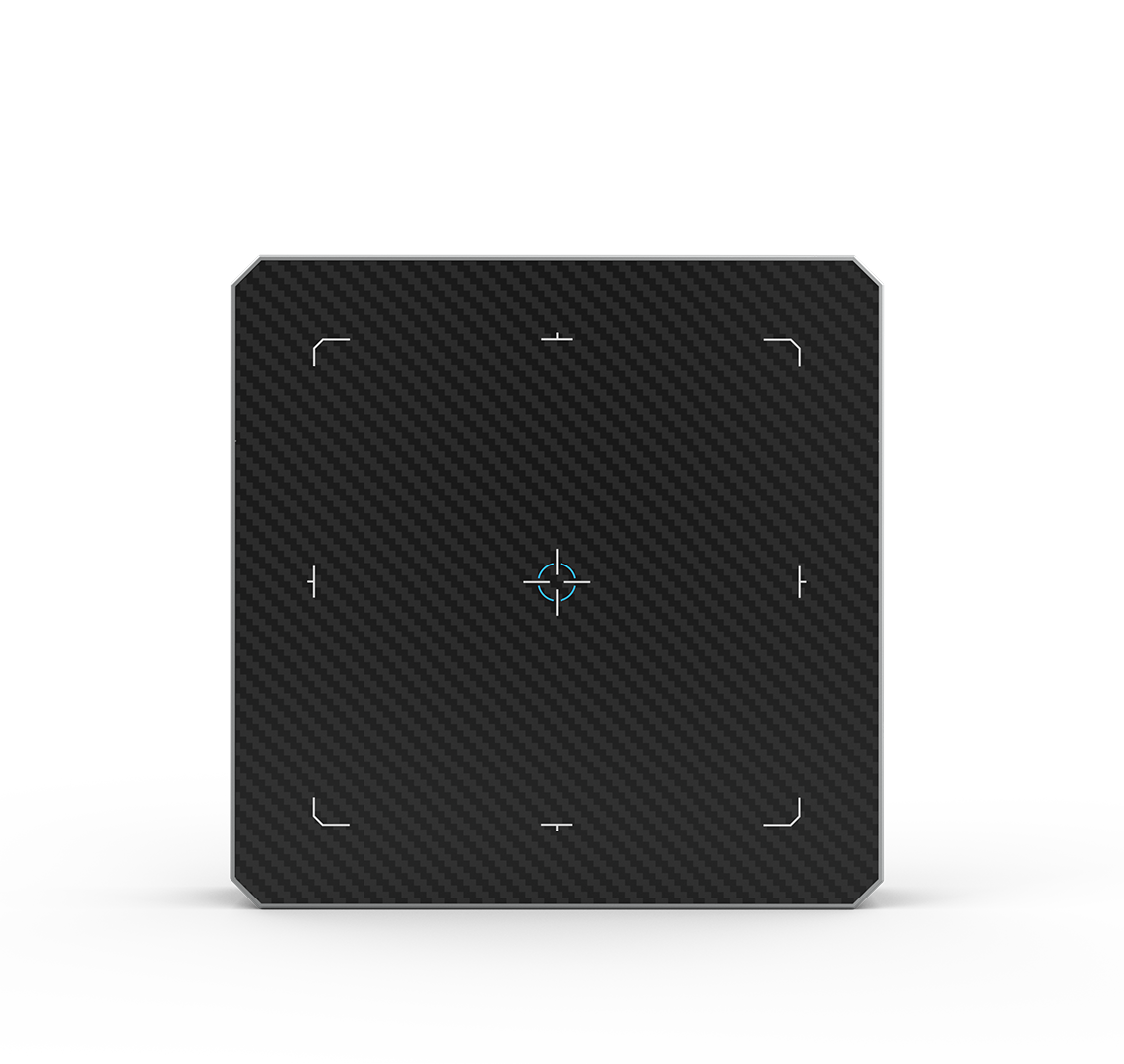

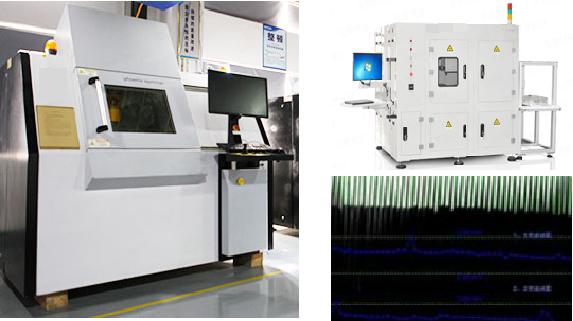

The X-Panel 1613a FDI and X-Panel 3025a FQI series X-ray flat panel detectors independently developed and designed by Haobo are specially developed for the application scenarios of industrial new energy lithium battery detection. They are real-time imaging amorphous silicon dynamic flat panel detectors. Characterized by high quality, large dynamic range and high imaging contrast. This fixed detector is designed with industrial grade standards, is durable, and features high radiation resistance, wide environmental adaptability and high reliability. The SDK software development kit provided by Shanghai Haobo supports Windows and Linux operating systems, allowing you to easily configure parameters, calibrate and capture images of the detector.

Hardware product recommendation

Post time: Jul-19-2022