The safe and continuous supply of energy plays a pivotal role in the development of the national economy. Long-distance pipeline transportation is an important channel for energy supply. It is a device connected by pipes, pipe connectors and valves. At the turning point of the pipeline or the connection of two pipelines, a circular weld can be seen. The quality of the weld has an important influence on the service life of the industrial pipeline. Therefore, the use of reasonable and effective technical means to strengthen the defect monitoring of industrial pipelines should promptly discover the defects in the welds, repair the defects in time, and maintain the integrity of the pipeline, which can reduce pipeline accidents and improve the economic and social benefits of pipeline energy transmission. benefit.

Radiography refers to a non-destructive testing method in which X-rays or γ-rays penetrate the test piece and use film as a device for recording information. This method is the most basic and the most widely used ray detection method. Radiographic inspection is suitable for most materials and product forms, such as welding, castings, composites, etc. The radiographic inspection film can generate an intuitive image of defects on the internal structure of the material, with accurate qualitative and quantitative, and the inspection results are directly recorded and can be stored for a long time. The detection rate of volumetric defects, such as pores and slag inclusions, is very high.

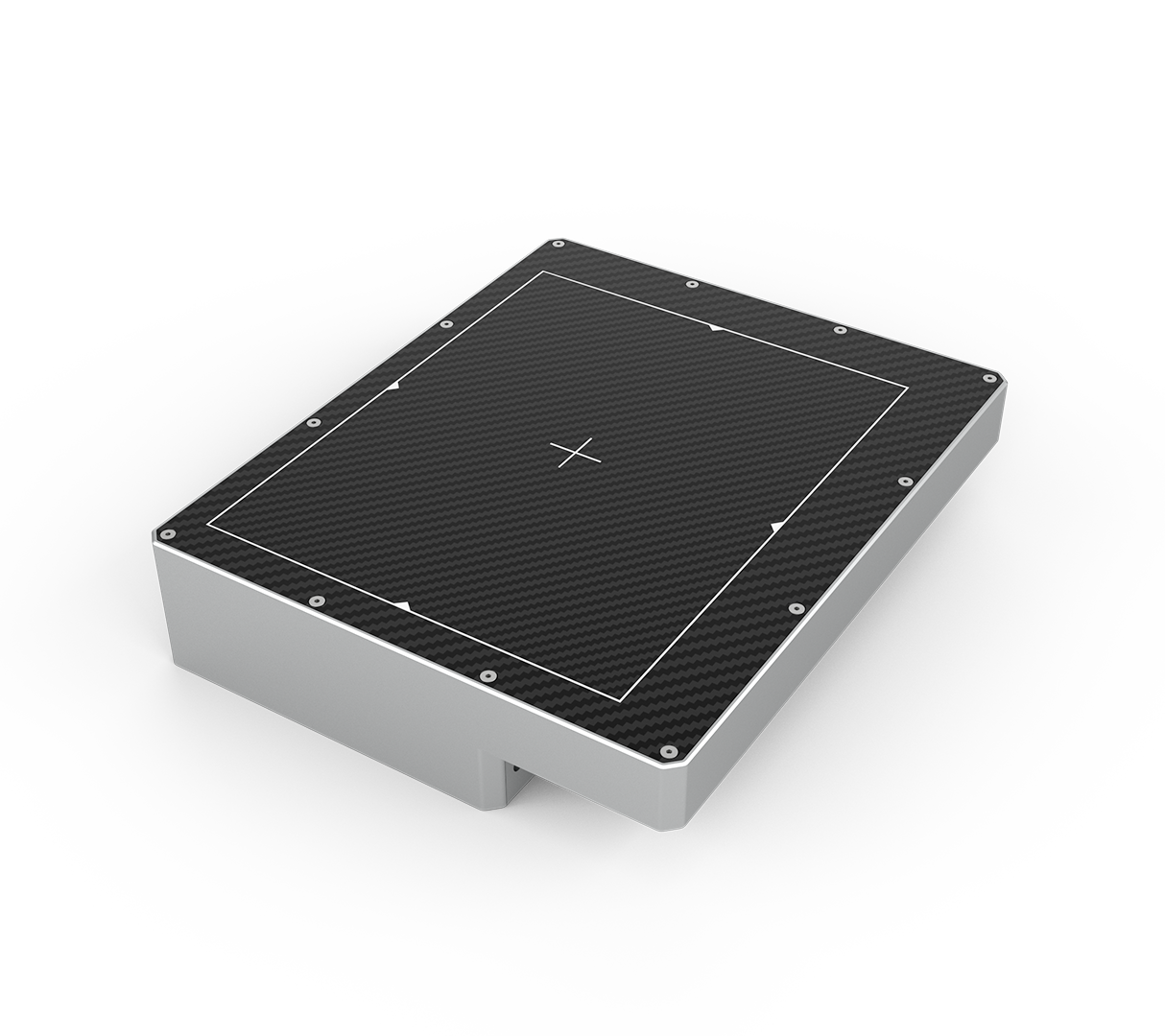

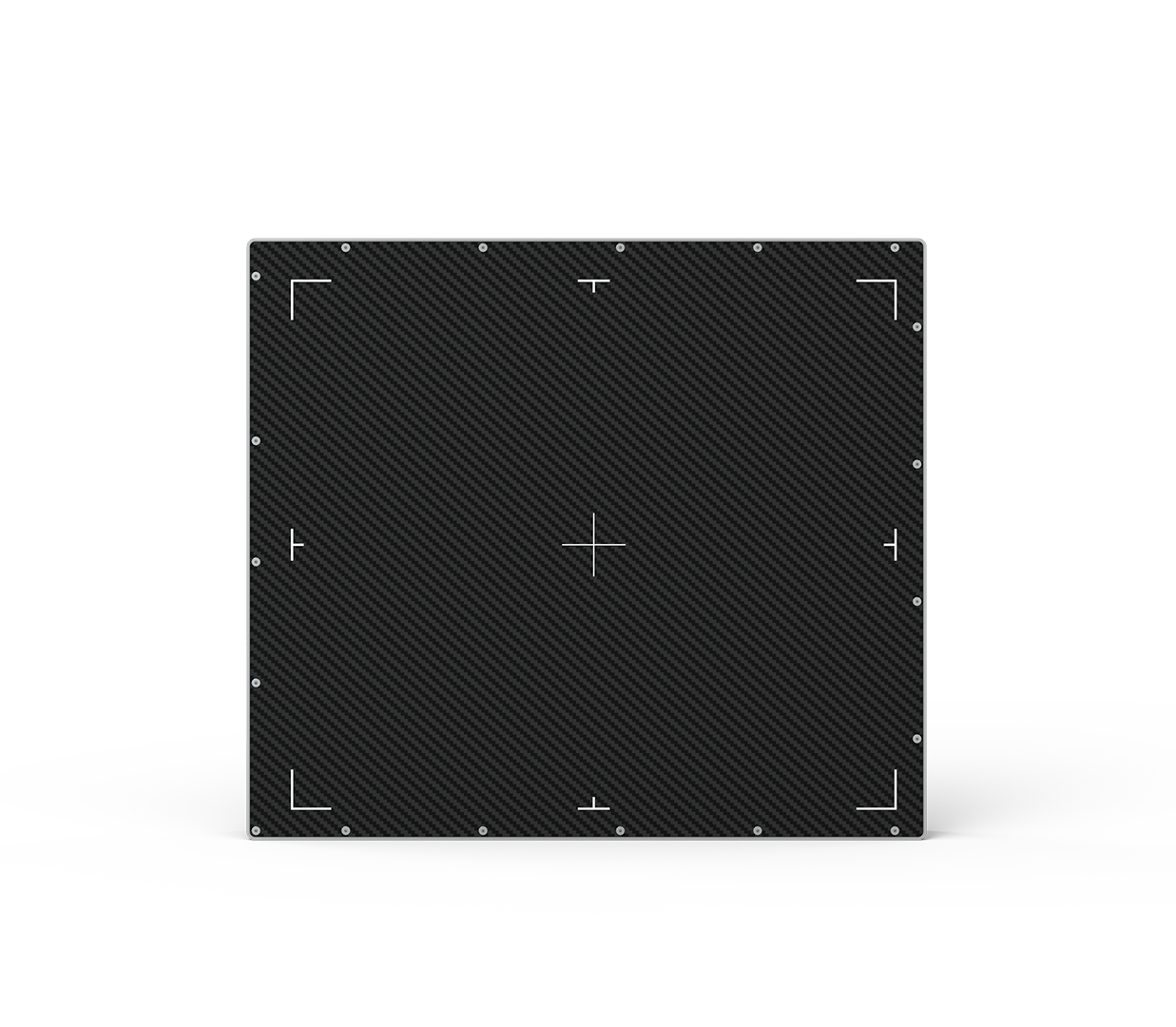

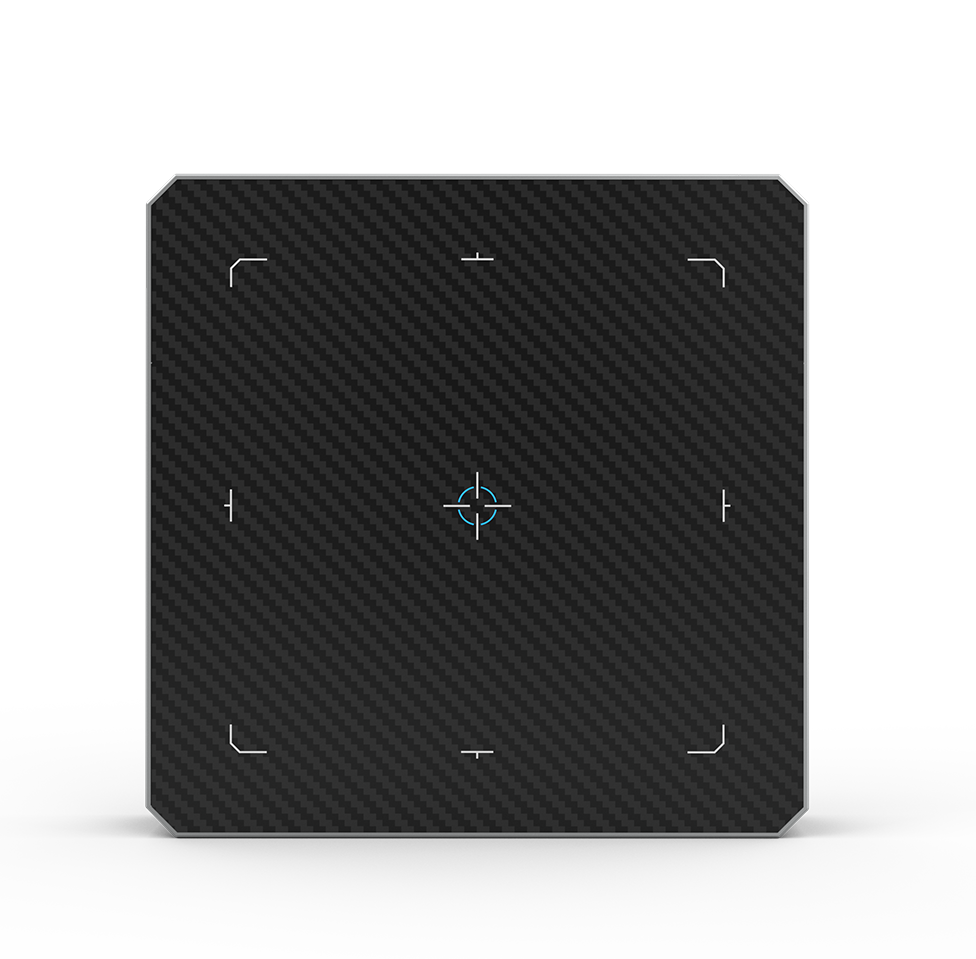

The X-Panel 1613a FDI and X-Panel 3025a FQI X-ray flat panel detectors independently developed and designed by Haobo are specially developed for the application scenarios of industrial CT. They are real-time imaging amorphous silicon dynamic flat panel detectors. Features large range and high imaging contrast. This fixed detector is designed with industrial grade standards, is durable, and features high radiation resistance, wide environmental adaptability and high reliability. The SDK software development kit provided by Haobo supports Windows and Linux operating systems, which allows you to easily configure parameters, calibrate and capture images of the detector. It is widely used in various industries such as castings, pipeline welds, and pressure vessels. Check the application.

Hardware product recommendation

Post time: Jul-19-2022